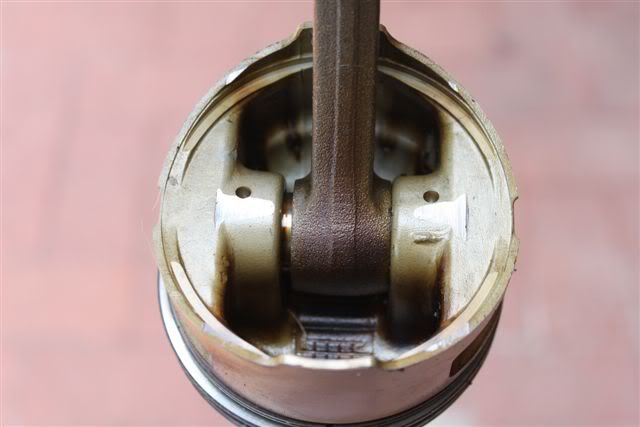

Here are some pictures regarding the two types of conrods for the 4G93T (standard V forged)

Massive difference!!

Here is a bent rod. I pushed my motor progressively.

This is cylinder number one rod, number 3 also got bent.

It only took an extra 3psi to bend it.

I measured the difference between a good one and this bent one (centre to centre), the difference in length was -4mm.

The engine developed a "death rattle", I knew what it was straight away and shut down. After it was pulled down it was found that the counter weight on the crank was hitting and removing metal from the bottom of the piston at bottom dead centre (i should upload a photo of this as well).

I was lucky! This could have been the precurser to sending something out through the block.

Each engine is different. You have heard the warnings regarding the weakness in the rods, now you have seen some pics.

Massive difference!!

Here is a bent rod. I pushed my motor progressively.

This is cylinder number one rod, number 3 also got bent.

It only took an extra 3psi to bend it.

I measured the difference between a good one and this bent one (centre to centre), the difference in length was -4mm.

The engine developed a "death rattle", I knew what it was straight away and shut down. After it was pulled down it was found that the counter weight on the crank was hitting and removing metal from the bottom of the piston at bottom dead centre (i should upload a photo of this as well).

I was lucky! This could have been the precurser to sending something out through the block.

Each engine is different. You have heard the warnings regarding the weakness in the rods, now you have seen some pics.