Super Top

Donating Members

I've read some things about the gearboxes of the HSG's are not very strong.

Is this true and what are the parts that usually break or wear out inside the gearbox?

Why am I asking? About a month ago the gearbox of my manual HSGR went.

I't won't go into second gear. And in the exceptional case it goes into second you can't get it out anymore.

Also it kicks out of gear when driving in reverse.

I learned from the dutch Mitsubishi community that the previous owner used the car for drags and sprint races.

Something the previous owner ofcourse didn't tell me.

When I took the gearbox off I let out the oil, it was completely black and smelled bunt.

I brought the box to a gearbox rebuilder in my neighbourhood. To check what's wrong with it.

At first we could not find much.

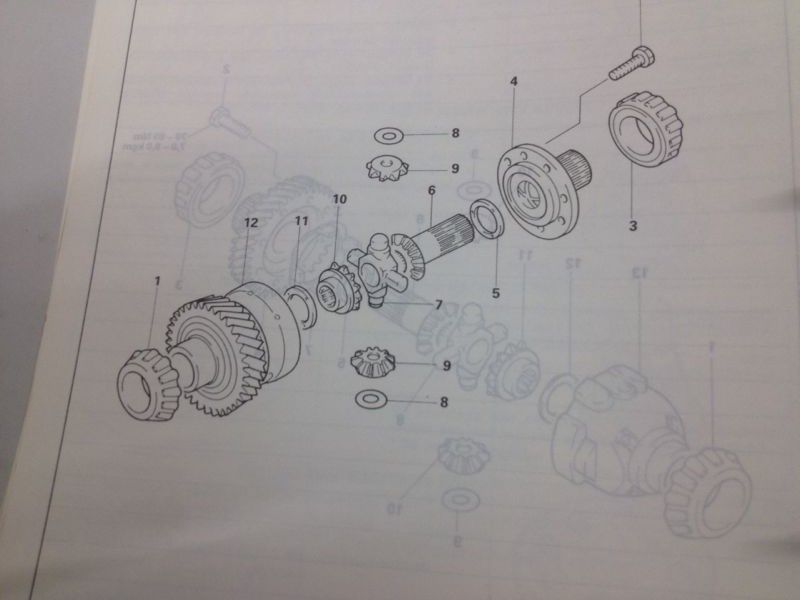

He found out that gearshift fork of second gear was worn out on one side.

The synchro's were a bit worn but not excessive. Same story for the hub, sleeve and keys that select second gear.

It all gets replaced just to be sure.

We could not find anything about reverse kicking out of gear.

I hope with replacing all of the bearings it will stay in gear again.

What are your experiences with these manual boxes?

Mine is a manual HSG-R has 137.000km's on it and is still completely stock.

Is this true and what are the parts that usually break or wear out inside the gearbox?

Why am I asking? About a month ago the gearbox of my manual HSGR went.

I't won't go into second gear. And in the exceptional case it goes into second you can't get it out anymore.

Also it kicks out of gear when driving in reverse.

I learned from the dutch Mitsubishi community that the previous owner used the car for drags and sprint races.

Something the previous owner ofcourse didn't tell me.

When I took the gearbox off I let out the oil, it was completely black and smelled bunt.

I brought the box to a gearbox rebuilder in my neighbourhood. To check what's wrong with it.

At first we could not find much.

He found out that gearshift fork of second gear was worn out on one side.

The synchro's were a bit worn but not excessive. Same story for the hub, sleeve and keys that select second gear.

It all gets replaced just to be sure.

We could not find anything about reverse kicking out of gear.

I hope with replacing all of the bearings it will stay in gear again.

What are your experiences with these manual boxes?

Mine is a manual HSG-R has 137.000km's on it and is still completely stock.